Roll over on the image to zoom

ABB Dry-Type Transformers | Up to 36 kV | 100 kVA – 20 MVA

🔍 Product Overview

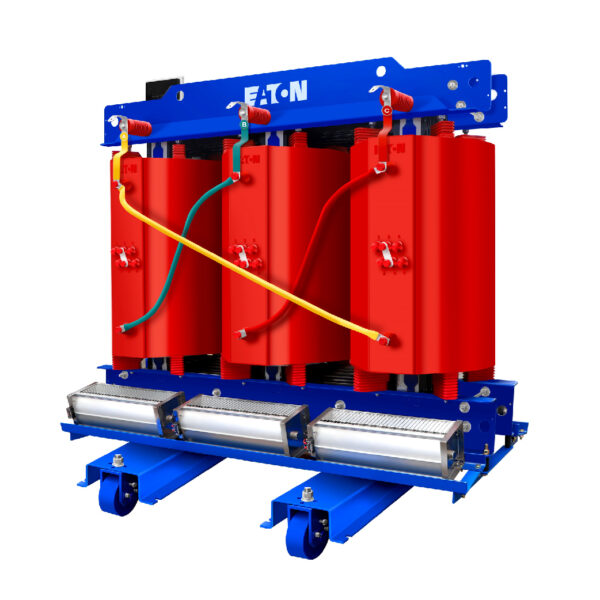

ABB Dry-Type Transformers are a safe, fire-resistant, and environmentally friendly alternative to oil-immersed transformers. Designed for indoor and outdoor use up to 36 kV and up to 20 MVA, these transformers are ideal for commercial, industrial, and utility applications where fire risk, environmental impact, and maintenance costs are key concerns.

ABB’s vacuum cast coil (VCC) and resin encapsulated technologies ensure excellent insulation, moisture resistance, and mechanical strength, even in harsh or high-humidity environments.

Description

Safe. Reliable. Low-Maintenance. | Up to 36 kV | 100 kVA – 20 MVA

📞 Call/WhatsApp: +254 707 122 122 | 🌐 shopstemaengineering.com

📐 ABB Dry-Type Transformer Technical Specifications

| Feature | Specification |

|---|---|

| Voltage Class | Up to 36 kV |

| Power Rating | 100 kVA – 20 MVA |

| Insulation Class | F or H (155°C / 180°C) |

| Cooling Methods | AN (Air Natural), AF (Air Forced) |

| Core Material | Cold Rolled Grain Oriented (CRGO) Silicon Steel |

| Technology | VPI (Vacuum Pressure Impregnated) / VCC (Vacuum Cast Coil) |

| Enclosure Options | IP00 (Open), IP23, IP54, NEMA Types |

| Ambient Temp Range | –25°C to +50°C |

| Overload Capacity | Up to 150% for short durations |

| Standards | IEC 60076-11, ANSI/IEEE, CSA, UL |

| Environmental Rating | E2 (Harsh environment), C2 (Cold), F1 (Fire behavior) |

🌟 Key Features

🔥 Fire Safety & Environmentally Friendly

-

No oil means zero risk of leakage or explosion

-

Self-extinguishing epoxy resin system

-

Complies with IEC fire performance classification F1

🌧️ Moisture & Pollution Resistant

-

Suitable for coastal, humid, or polluted zones

-

Can operate without climate-controlled rooms

⚙️ Rugged & Low Maintenance

-

Solid insulation structure resists mechanical shocks

-

No need for oil testing or refilling

-

Minimal service over 30+ years of life

📶 Compact & Versatile

-

Small footprint, ideal for indoor spaces

-

Easily integrated in modular substations, data centers, tunnels

🏭 Ideal Applications for ABB Dry-Type Transformers

| Sector | Use Cases |

|---|---|

| Commercial | Shopping malls, hotels, airports, office buildings |

| Industrial | Food processing, steel plants, chemical and textile plants |

| Renewable Energy | Wind & solar inverters and substations |

| Data Centers | Server farms, IT load centers |

| Tunnels & Rail | Underground metro, tunnel lighting, traction systems |

| Marine & Offshore | Ships, oil rigs, port infrastructure |

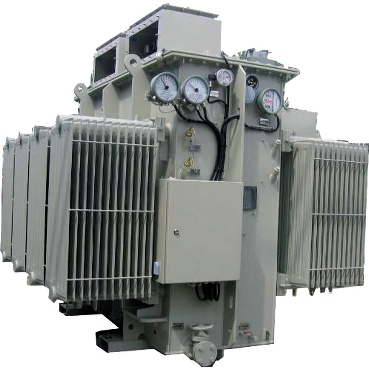

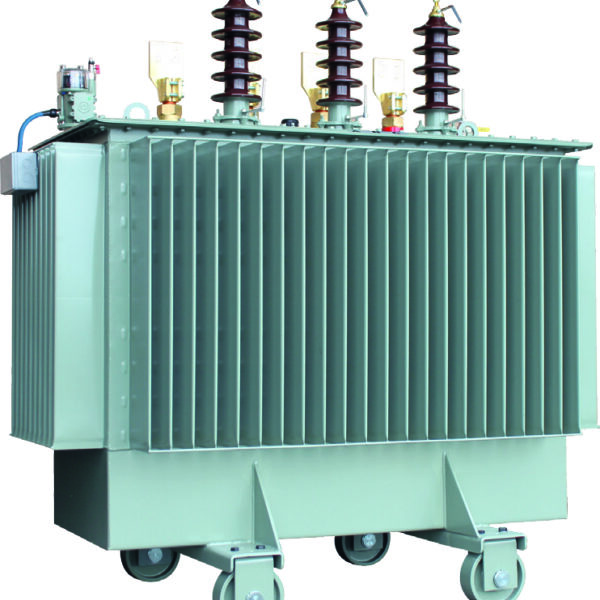

🆚 Dry-Type vs Oil-Immersed Transformers

| Feature | ABB Dry-Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Fire Risk | Very Low (self-extinguishing) | Moderate (requires containment) |

| Cooling | Air (natural or forced) | Oil with radiators or pumps |

| Environmental Risk | None (no oil) | Risk of oil spillage |

| Maintenance | Minimal | Requires regular oil testing |

| Installation | Indoors or outdoors | Mostly outdoors |

| Size & Weight | More compact | Bulkier |

| Upfront Cost | Slightly higher | Lower |

| Noise Levels | Lower (suitable for buildings) | Higher |

⚙️ Customizable Options

| Configurable Item | Available Choices |

|---|---|

| Enclosure | IP00 (open), IP23, IP54, stainless steel, NEMA |

| Tap Changer | Off-circuit tap links or automatic |

| Mounting Options | Skid, floor, wall-mounted |

| Connection Terminals | Copper/Aluminum bars or cable boxes |

| Temperature Monitoring | RTDs, digital thermal relays, fans |

| Harmonic Filters | Optional for non-linear load environments |

🔧 Sample Configurations

| Model | Power (kVA) | Voltage (kV) | Application |

|---|---|---|---|

| ABB DT-VCC-2500 | 2,500 kVA | 33/0.4 kV | Industrial motor control station |

| ABB DT-IP54-1600 | 1,600 kVA | 11/0.415 kV | Commercial high-rise building |

| ABB DT-WIND-3150 | 3,150 kVA | 33/0.69 kV | Wind farm collector transformer |

| ABB DT-DATA-1000 | 1,000 kVA | 22/0.415 kV | Edge data center application |

🛡️ Compliance & Safety

-

✔️ IEC 60076-11 Certified

-

✔️ UL/CSA/ANSI compliant for North American projects

-

✔️ ISO 9001 / 14001 / 45001 production facilities

-

✔️ Type-tested for: dielectric strength, heat rise, impulse voltage

-

✔️ Meets environmental class E2, climate class C2, fire class F1

🛠️ Services from Shop Stema Engineering

-

🔧 Transformer sizing, CAD drawings, and site layout planning

-

🏗️ Delivery, craning, and installation of enclosed or skid-mounted units

-

💡 Indoor ventilation and ambient temp analysis

-

⚡ On-site testing: insulation resistance, surge, temperature rise

-

🔄 Replacement of legacy oil-filled units with dry-type systems

📞 Need a Transformer Today?

Looking for fire-safe, eco-friendly ABB dry-type transformers for your facility, data center, or industrial site?

📞 Call/WhatsApp: +254 707 122 122

📧 Email: info@stemaengineering.com

Avis

Il n’y a pas encore d’avis.